Test of Yunsor Radiant Panel and its Comparison with Ecosun 300 Panel

A video appeared on a publicly accessible web page http://www.youtube.com/watch?v=dXFjhFtbECw&feature=related, where the panel ECOSUN 300U is compared with a product of the Chinese company YUNSOR. It is clear from the course of the test and its conclusions that the manufacturer does not have sufficient knowledge in the field of thermodynamics and his conclusions are entirely misleading:

- The conditions under which the tests are performed prove the lack of technical equipment as well as theoretical knowledge of operators

- The main principle of the heating panel is not to be heated to the highest possible temperature, it rather shows evidence of a poor ability to transmit heat by radiation in the infrared spectrum. Thus, the test result showing an insignificant difference in the surface temperature between the Ecosun 300 panel with the input of 300 W and the Yunsor panel with the input of 206 W is detrimental to the YUNSOR panel, contrary to the lay conclusion of the manufacturer. The YUNSOR panel overheats in the test because it is unable to transmit heat to the surrounding area, thus performing wrongly its basic function of an infrared heater.

- Temperature is measured by pyrometer, without accurate knowledge of the emissivity of measured surface, which has no predicative ability. Surface temperature of radiators must always be measured by a thermostat with a touch probe only! Generally, the higher is the emissivity of surface, the lower is the surface temperature of radiator at a given input. The surface of ECOSUN panels is provided with a special coating Thermoquartz and Thermocrystal and has proven emissivity of 0.96.

- Competing products using different types of coating have the surface emissivity between 0.70 and 0.85. The surface finish of Yunsor panel is in the same range.

- Surface temperature must be measured in a constant temperature and it is not clear from the test if this basic condition has been met.

As we were interested in the actual performance of this product, we put one piece to tests in our laboratory. That is why we acquired a YUNSOR panel with the following parameters. :

Measured values: Power input: 206 W, Power input: 230 V, IP protection: product without a label undetected.

Visual evaluation of the product brought a finding having a crucial impact on the safe operation:

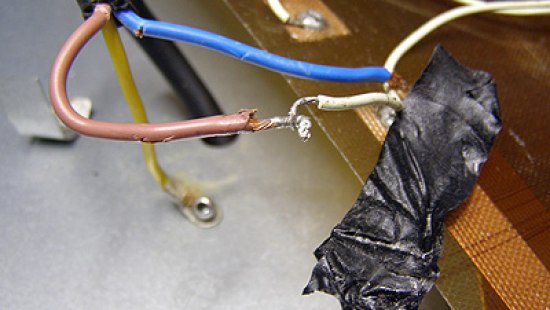

The product stopped working during the test. After opening it was found that the internal connections were made with twisted wires and negligent tinning (tin softens at temperatures that can be reached in the product and so it is not suitable for this use). The connection was broken and insulated with a PVC tape the temperature resistance of which is usually up to 70 °C. The connection made in this way is mortal as it can lead to seasoning and breakdown to the panel chassis.

Another serious defect was damage to the supply lead that was cut through with a piece of tin used to fasten the lead. Again, this is a defect with a crucial impact on the safety of the product

The declared "crystal" technology of the heating element consists in the use of graphite paste applied between electroinsulating panels. This solution was used in the 1950's and 1960's before the technology of radiant heating films and is technically obsolete.

For comparison, ECOSUN 300 with the following parameters was used: Power input: 289 W, Voltage: 230 V, IP protection: 44

Then efficiency of individual heaters was compared: First, we conducted tests on the YUNSOR product and then we changed the front part, which has a major impact on the efficiency of radiant effect, for the front radiant plate of the ECOSUN panel, bearing THERMOQUARZ® inner layer THERMOCRYSTAL® outer layer, the other components remained the same. Measurements were carried out in an air-conditioned laboratory, where a constant temperature of the surrounding air was maintained.

| Panel | Panel centre | Back | Ambient temperature |

|---|---|---|---|

| Yunsor | 100,45 °C | 40,15 °C | 24,5 °C |

| Yunsor with Thermoquarz® and Thermocrystal® | 94,45 °C | 38,75 °C | 24,5 °C |

| ECOSUN 300 | 114,5 °C | 53,81 °C | 24,5 °C |

Measurement of panel surface temperature with an attachable thermostat. The probe was always placed on the product for 24 hours in order to achieve a steady temperature. The back of the panel was also measured to verify that the heat does not escape mainly from the rear part, which is undesirable. The results indicate that the surface treatments Thermoquarz® and Thermocrystal® have a major impact on increasing the panel radiation, contrary to the original YUNSOR finish. The panel provided with Thermoquarz® and Thermocrystal® does not overheat so much with the same power input and ambient temperature, radiation is increased significantly and less heat is getting on the back of the panel. To determine the efficiency of the product it is important to measure the ability of heat emission. For this test we used black targets placed at distances of 0.5, 1.5 and 1.5 m from the panel.

| Panel | 0,5 m | 1,0 m | 1,5 m | Ambient temperature |

|---|---|---|---|---|

| Yunsor | 32,4 °C | 27,3 °C | 25,5 °C | 24,5 °C |

| Yunsor with Thermoquarz® and Thermocrystal® | 32,3 °C | 27,7 °C | 25,6 °C | 24,5 °C |

| ECOSUN 300 | 33,9 °C | 28,8 °C | 26,3 °C | 24,5 °C |

Conclusion:

The tests clearly show that the radiant panel Yunsor does not have the promised parameters and does not meet the parameters of E 300, either. Leaving aside the very poor technical processing of the product which is hazardous to operators and may lead to an injury. Long life of the product is doubtful due to the outdated concept of the heating element.