FENIX Filaments for 3D Printing

The idea of producing filaments (printing strings) for 3D printers has existed for a long time, but the dynamic growth between 2014 and 2022 left no room to implement this idea. However, the economic and energy crisis, which began in the second half of 2021, will be reflected in our industry by the end of 2022 by market stagnation and a decline in demand for heating cables. The production of 3D filaments was then just a logical step to use the vacant capacity of the production lines for heating cables.

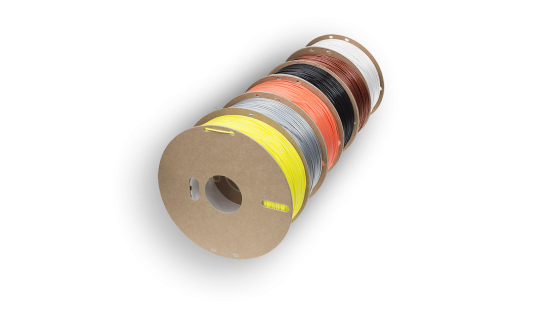

In the beginning, the most common PLA*) filaments in six basic colours were included. The production uses high quality American-made granulate that is designed specifically for 3D filaments, is odourless, bubble-free, has high diameter accuracy and is compatible with most 3D printers.

Technical parameters of FENIX 3D filaments:

- Available colours: white, black, copper, aluminium, fluorescent orange and yellow

(WARNING: fluorescent colours are not UV stable) - Material: PLA

- String diameter: 1.75 mm

- Diameter tolerance: ±0.05 mm

- Winding length: 340 m

- Weight: 1 kg

- Wound on paper spool ø 200 mm, width 65 mm, inner hole ø 56 mm

Print parameters:

- Nozzle temperature: 210–225 °C

- Pad temperature: 60 °C

In the future, it is planned to expand the range of colours offered and to produce filaments from other materials.

*) PLA (polylactic acid) is a fully biodegradable material (bioplastic), which is one of the most commonly used materials for 3D printing using the thermoplastic extrusion method. In terms of durability, flexibility and hardness it has the same properties as other plastics – it can be further processed by hand grinding, drilling and painting. The disadvantage is the ability to absorb air moisture (manifested by the formation of bubbles on the surface), so it is necessary to ensure storage in a dry environment.